1. Gas Networks: SD TUBES steel pipes, CE certified and produced according to EN 10255/Medium Series

2. Fire Extinguishing Networks: SD TUBES IBS-PYRO steel pipes produced according to EN 10255/Medium Series with grooved ends.

3. Water and Heating:

SD TUBES steel pipes, produced according to EN 10255/Medium Series.

SIDENOR steel pipes are the “safe choice” for both the installation technician and the end-user, being superior to the standard steel tubes, due to the production method and high quality standards applied.

Steel pipes produced according to EN 10255, CE certified, hot-dip galvanized, self-colored or black coated that cover all requirements for natural gas, fire protection, water supply and heating networks

STEEL GRADE:

HRC in grade S195T according to EN 10020

PRODUCTION:

Hot stretch reducing production with full body

LENGTH:

Standard lengths of 6m are produced with tolerance -0+50mm

Other lengths are produced upon request

PACKING – WEIGHT:

Bundles weight is varying from 800 to 1,400 kg, depending on dimensions

PIPES ENDS:

• With threads (ΕΝ 10226-1 conical) and couples (ΕΝ 10241)

• Grooved or plain ends

COATINGS

• Galvanized according to EN 10204/ A1 or A2

• Black coated or self colored

|

WATER PIPES ΕΝ 10255 |

|||||||||||||

|

Nominal External Diameter |

SD TUBE

Medium Series |

SD TUBE Type L |

|||||||||||

| DΝ (mm) | D (mm) | R (in) | External

Diameter |

Wall

Thickness |

Mass Self-coloured

Pipes (kg/m) |

External

Diameter |

Wall

Thickness |

Mass Length Unit of

Self-coloured Pipes (kg/m) |

|||||

| Max (mm) | Min

(mm) |

(mm) | ΑΒ * | ΒΜ * | Max

(mm) |

Min (mm) | (mm) | ΑΒ * | ΒΜ * | ||||

| 15 | 21,3 | 1/2″ | 21,8 | 21,0 | 2,6 | 1,20 | 1,20 | 21,7 | 21,0 | 2,3 | 1,08 | 1,09 | |

| 20 | 26,9 | 3/4″ | 27,3 | 26,5 | 2,6 | 1,60 | 1,60 | 27,1 | 26,4 | 2,3 | 1,40 | 1,41 | |

| 25 | 33,7 | 1″ | 34,2 | 33,3 | 3,2 | 2,40 | 2,40 | 34,0 | 33,2 | 2,9 | 2,20 | 2,22 | |

| 32 | 42,4 | 1 1/4″ | 42,9 | 42,0 | 3,2 | 3,10 | 3,10 | 42,7 | 41,9 | 2,9 | 2,82 | 2,85 | |

| 40 | 48,3 | 1 1/2″ | 48,8 | 47,9 | 3,2 | 3,60 | 3,60 | 48,6 | 47,8 | 2,9 | 3,25 | 3,29 | |

| 50 | 60,3 | 2″ | 60,8 | 59,7 | 3,6 | 5,00 | 5,10 | 60,7 | 59,6 | 3,2 | 4,51 | 4,58 | |

| 65 | 76,1 | 2 1/2″ | 76,6 | 75,3 | 3,6 | 6,40 | 6,50 | 76,0 | 75,2 | 3,2 | 5,75 | 5,87 | |

| 80 | 88,9 | 3″ | 89,5 | 88,0 | 4,0 | 8,40 | 8,50 | 88,7 | 87,9 | 3,2 | 6,76 | 6,93 | |

| 100 | 114,3 | 4″ | 115,0 | 113,1 | 4,5 | 12,20 | 12,50 | 113,9 | 113,0 | 3,6 | 9,83 | 10,10 | |

| 150 | 168,3 | 6″ | 169,9 | 166,6 | 5,0 | 20,13 | 20,40 | – | – | – | – | – | |

|

STEEL TUBES ELOT EN 10255 / MEDIUM SERIES WITH GROOVED ENDS FIRE EXTINGUISHING NETWORKS |

|||||||

|

Nominal External Diameter |

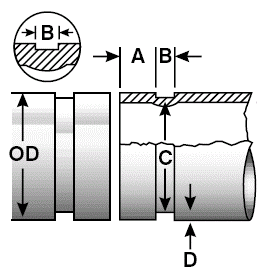

Diameter Tolerance | Grooved Diameter C |

Grooved Depth D |

||||

|

R (in) |

D (mm) | Wall Thickness

(mm) |

+

(mm) |

–

(mm) |

Basic Tolerance + 0mm |

(mm) |

|

| 2″ | 60,3 | 3,6 | 0,50 | 0,60 | 57,15 | -0,38 | 1,6 |

| 2 1/2″ | 76,1 | 3,6 | 0,50 | 0,80 | 72,26 | -0,46 | 1,98 |

| 3″ | 88,9 | 4,0 | 0,60 | 0,90 | 84,94 | -0,46 | 1,98 |

| 4″ | 114,3 | 4,5 | 0,70 | 1,20 | 110,08 | -0,51 | 2,11 |

Dimension from end (Α): 15,88 ± 0,76mm

Grooved width (Β): 8,74 ± 0,76mm

Notes: Other tolerances of thickness and weight are produced according to ΕΝ 10255

|

SIDENOR STEEL INDUSTRY SA (ATHENS) – Export Dept. |

|

| Address: | 33, Amaroussiou-Chalandriou street |

| Postal Code: | GR-15125 |

| City: | Athens |

| Area: | Attiki |

| Country: | GREECE |

| Telephone: | (+30)-210-6787767 |

| Fax: | (+30)-210-6787740 |

|

ERLIKON WIRE PROCESSING SA (ATHENS) – Export Dept. |

|

| Address: | 252, Pireos str. |

| Postal Code: | GR-17778 |

| City: | Athens |

| Area: | Attiki |

| Country: | GREECE |

| Telephone: | (+30)-210-4898202 |

| Fax: | (+30)-210-4898391 |

|

ERLIKON WIRE PROCESSING SA (THESSALONIKI) – Export Dept. |

|

| Address: | 12th km National Road Thessaloniki-Veria |

| Postal Code: | GR-57008 |

| City: | Thessaloniki |

| Area: | Ionia |

| Country: | GREECE |

| Telephone: | (+30)-2310-790250 |

| Fax: | (+30)-2310-722288 |

|

PROSAL TUBES SA (BULGARIA) – Export Dept. |

|

| Address: | 1, Vladaisko Vastanie |

| Postal Code: | BG-2304 |

| City: | Sofia |

| Area: | Pernik |

| Country: | BULGARIA |

| Telephone: | (+35)-976-681356 |

| Fax: | (+35)-976-681357 |