SD stirrup reinforcing mesh for beam, column and shear wall stirrups is produced from straight rebars – grade B500B according to DIN 488 in diameters 8, 10, and 12mm. The stirrup cages are then formed in fabrication plants or in job site, leading to high precision in geometry, stirrup distance and stability.

The forming of the stirrup cages from SD mesh is considerably faster, accurate and covers most of the cross-section geometries of beams, columns and shear walls, offering high precision in execution with high productivity and overall quality.

Product Applications

COLUMNS

The more demanding Earthquake-Resistance Building Codes have led to the increased need for plasticity of reinforced concrete members which in turn has led to increased need of confinement and thus more stirrup reinforcement in more demanding shapes.

SD Reinforcing Mesh for column stirrups have large development lengths, making possible the forming of complex and large stirrups (by continuous bending). The geometry and free edges of the SD column meshes make possible the forming of double hooks at 135o, even for small rectangular cross-sections.

SD Reinforcing Mesh for column stirrups are made from SD Rebars of Class C (B500C) in diameters of 8, 10 , 12 mm with stirrup distance at 100mm and development lengths from 1.00m to 3.00m. Other configurations are also available upon request. The SD Reinforcing Mesh for column stirrups covers most of the needs for lateral reinforcement found in today’s reinforced concrete structures.

BEAMS

In the most common reinforced concrete structures, beam stirrup shapes are usually of rectangular shape with two or four vertical ties (stirrup legs) depending on beam width. The stirrup cage can be easily formed using SD mesh.

SD Reinforcing Mesh for beam stirrups in large development lengths allow the formation of the lateral reinforcement of high-beams (for example foundation beams, bridge girders etc.) Their design characteristics also make possible the formation of 135o end-hooks and adaptation to large variety of cross-section shapes.

WALLS

Shear walls or wall-like columns are members with higher shear strength and horizontal load bearing capacity and with continuously increasing usage in modern reinforced concrete structures. Wall reinforcement is usually formed with end-columns of rectangular shape and need of confinement connected with 2D curtain reinforcement. Wall-like columns can have different shapes such as (T), (Γ), (Π) the lateral reinforcement of which can to be formed using bent SD Reinforcing Mesh.

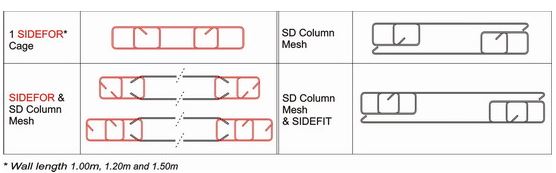

SD Reinforcing Mesh together with the prefabricated SIDEFOR stirrup cages offer a variety of high-quality solutions for the reinforcement of shear-walls and wall-like columns as shown below in Table 1.

All applicable methods offer similar advantages such as:

- Greater stability and accuracy of geometry of the reinforcement due to industrial-controlled production

- Faster and problem-free forming and fitting

- High level of accuracy in design implementation

Table 1

Most of the usual shapes and geometries of walls or wall-like columns can be addressed by using SD Reinforcing Mesh either in combination with or without SIDEFOR cages. Tailor-made solutions can also be offered for larger wall geometries through the usage of SIDEFIT family of mesh products.

Spacing between stirrups

On the steel cage formed after the forming of the mesh, the spacing between the stirrups is 100 or 125mm, while the main reinforcement length is up to 3m.

Special design and placement of retaining wires

The line retaining wires are intended to keep the transverse bars in place. In SD Stirrup Reinforcement Mesh the number, the diameter and the position of retaining wires have been designed so as to facilitate the forming of the mesh and ensure the stability of the finished item until it is incorporated into the construction.

Stirrups formed from straight High Ductility SD Steel bars

In SD Stirrup Reinforcement Mesh the main reinforcement is manufactured from straight SD Class C Steel bars (B500C – ELOT 1421), which ensures an accurate geometry that enables easy forming, exact adherence to design, and the avoidance of problems related to the movement of stirrups during fitting and pouring of concrete.

Diameter and spacing of stirrups according to designs

In current designs for earthquake safety of structural reinforcement, stirrups are placed closer to each other, which means that their number increases, while stirrups of 12mm in diameter are now widely used. SIDENOR’s SD Stirrup Reinforcement Mesh, with a spacing of 100mm between transverse bars and the possibility to use stirrups of 12mm in diameter, meets almost all requirements for transverse reinforcement in reinforced concrete constructions.

Possible creation of double support hook 135°

For the incorporation of the stirrups into beams, columns and walls, the EKOS 2000 (Greek Regulation for Concrete Reinforcement) requires the creation of a support hook at both ends of the stirrups, with an angle equal to or larger than 135° and the length specified by the EKOS 2000 Regulation. SD Stirrup Reinforcement Mesh is designed to offer this possibility during forming.

Creation of “continuous” stirrups

With regard to new earthquake-safe constructions, the design of transverse reinforcement for columns and walls requires the creation of complex supporting stirrups. Up to now, most of these stirrups have been created with the use of simple stirrups. SD Stirrup Reinforcement Mesh is also manufactured in large sizes, enabling the creation of almost every kind of complex stirrups.

| TYPE | Prefabricated mesh for stirrup reinforcement for columns, beams and shear walls |

| STEEL GRADE | Line wires: concrete reinforcing steel, grade B500B according to DIN488, diameter Ø8, Ø10 and Ø12

Cross wires: SAE 1010 wire rod, according to ASTM A510M |

| FORM – DIAMETER | Sheets: length from 0.80 to 3.00m and width 2.60 to 3.00m |

| PACKING WEIGHT | Sheet stacks: weight from 9.60 to 73.30Kg per sheet, depending on dimensions and type |

| Theoretical weights and bundles | |||||||||

| Φ8 | 100mm spacing | 125mm spacing | |||||||

| Sheet Length | x | Sheet Width | Sheet weight (kg) |

No. of sheets per bundle |

Theor. bundle weight (kg) |

Sheet weight (kg) |

No. of sheets per bundle |

Theor. bundle weight (kg) |

|

| 0.80 | X | 3.00 | 11.48 | 30 | 344 | 9.60 | 30 | 288 | |

| 1.00 | X | 3.00 | 13.85 | 30 | 416 | 10.84 | 30 | 325 | |

| 1.20 | X | 3.00 | 16.22 | 30 | 487 | 13.37 | 30 | 401 | |

| 1.40 | X | 3.00 | 18.59 | 30 | 558 | 15.27 | 30 | 458 | |

| 1.60 | X | 3.00 | 21.62 | 30 | 649 | 17.83 | 30 | 535 | |

| 1.80 | X | 3.00 | 23.99 | 30 | 720 | 19.73 | 30 | 592 | |

| 2.00 | X | 3.00 | 27.03 | 30 | 811 | 22.29 | 30 | 669 | |

| 2.20 | X | 3.00 | 29.40 | 30 | 882 | 24.19 | 30 | 726 | |

| 2.40 | X | 3.00 | 31.77 | 30 | 953 | 26.08 | 30 | 782 | |

| 2.60 | X | 3.00 | 34.81 | 15 | 522 | 27.98 | 15 | 420 | |

| 2.80 | X | 2.60 | 32.22 | 15 | 483 | 26.11 | 15 | 392 | |

| 3.00 | X | 2.60 | 34.85 | 15 | 523 | 27.77 | 15 | 417 | |

| Φ10 | 100mm spacing | 125mm spacing | |||||||

| Sheet Length | x | Sheet Width | Sheet weight (kg) |

No. of sheets per bundle |

Theor. bundle weight (kg) |

Sheet weight (kg) |

No. of sheets per bundle |

Theor. bundle weight (kg) |

|

| 1.00 | X | 3.00 | 20.51 | 30 | 615 | ||||

| 1.20 | X | 3.00 | 24.21 | 30 | 726 | 19.77 | 30 | 593 | |

| 1.40 | X | 3.00 | 27.91 | 30 | 837 | 22.73 | 30 | 682 | |

| 1.60 | X | 3.00 | 32.28 | 30 | 968 | 26.36 | 30 | 791 | |

| 1.80 | X | 3.00 | 35.98 | 30 | 1079 | 29.32 | 30 | 880 | |

| 2.00 | X | 3.00 | 40.35 | 30 | 1211 | 32.95 | 30 | 989 | |

| 2.20 | X | 3.00 | 44.05 | 30 | 1321 | 35.91 | 30 | 1077 | |

| 2.40 | X | 3.00 | 47.75 | 30 | 1432 | 38.87 | 30 | 1166 | |

| 2.60 | X | 3.00 | 52.86 | 15 | 793 | 41.83 | 15 | 627 | |

| 2.80 | X | 2.60 | 48.38 | 15 | 726 | 39.17 | 15 | 587 | |

| 3.00 | X | 2.60 | 52.17 | 15 | 783 | 41.76 | 15 | 626 | |

| Φ12 | 100mm spacing | ||||||||

| Sheet Length | x | Sheet Width | Sheet weight (kg) |

No. of sheets per bundle |

Theor. bundle weight (kg) |

||||

| 1.20 | X | 3.00 | 33.97 | 15 | 510 | ||||

| 1.40 | X | 3.00 | 39.29 | 15 | 589 | ||||

| 1.60 | X | 3.00 | 45.29 | 15 | 679 | ||||

| 1.80 | X | 3.00 | 50.62 | 15 | 759 | ||||

| 2.00 | X | 3.00 | 56.61 | 15 | 849 | ||||

| 2.20 | X | 3.00 | 61.94 | 15 | 929 | ||||

| 2.40 | X | 3.00 | 67.27 | 15 | 1009 | ||||

| 2.60 | X | 3.00 | 73.26 | 15 | 1099 | ||||

| 2.80 | X | 2.60 | 68.11 | 15 | 1022 | ||||

| 3.00 | X | 2.60 | 73.30 | 15 | 1100 | ||||

Mesh of 2.80m and 3.00m lengths, is also produced with 3.00m width

| SIDENOR SA (ATHENS) – Export Dept. | |

| Address: | 33, Amaroussiou-Chalandriou street |

| Postal Code: | GR-15125 |

| City: | Athens |

| Area: | Attiki |

| Country: | GREECE |

| Telephone: | (+30)-210-6787111 |

| Fax: | (+30)-210-6787740 |

| e-mail: | info@sidenor.vionet.gr |

| SIDENOR SA (THESSALONIKI) – Export Dept. | |

| Address: | 12th km National Road Thessaloniki-Veria |

| Postal Code: | GR-57008 |

| City: | Thessaloniki |

| Area: | Ionia |

| Country: | GREECE |

| Telephone: | (+30)-2310-790111 |

| Fax: | (+30)-2310-722288 |

| e-mail: | info@sidenor.vionet.gr |

| GENECOS SA (FRANCE) | |

| Address: | 19, Rue de Passy |

| Postal Code: | FR-75016 |

| City: | Paris |

| Area: | Paris |

| Country: | FRANCE |

| Telephone: | (+33)-1-45270754 |

| Fax: | (+33)-1-45270708 |

| e-mail: | genecos@genecos.vionet.gr |

| METAL AGENCIES LTD (UK) | |

| Address: | Suite 4, Cobb House, 2-4 Oyster Lane |

| Postal Code: | KT14 7DU |

| City: | Surrey |

| Area: | Byfleet |

| Country: | UNITED KINGDOM |

| Telephone: | (+441)-932-331111 |

| Fax: | (+441)-932-331190 |

| e-mail: | sales@metalagencies.com |

| TEPRO METALL Vertriebs GmbH (GERMANY) | |

| Address: | Ursulastrasse 33-41 |

| Postal Code: | DE-50354 |

| City: | Hurth |

| Area: | Hurth |

| Country: | GERMANY |

| Telephone: | (+492)-233-790361 |

| Fax: | (+492)-233-790366 |

| e-mail: | mbeissel@teprometal.vionet.gr |

| SIDEROM STEEL SLR (ROMANIA) | |

| Address: | 42, Drumul Intre Tarlale Street 3rd Sector |

| Postal Code: | 032982 |

| City: | Bucharest |

| Area: | Bucharest |

| Country: | ROMANIA |

| Telephone: | (+402)-1-2090138 |

| Fax: | (+402)-1-2090365 |

| e-mail: | |

| SIDERAL STEEL Shpk (ALBANIA) | |

| Address: | Autostrada Tirane – Durres km 24 |

| Postal Code: | |

| City: | Tirane |

| Area: | Sukth |

| Country: | ALBANIA |

| Telephone: | (+355)-568-7574111 |

| Fax: | (+355)-568-7574510 |

| e-mail: | info@sideral.vionet.gr |

| SIDEBALK STEEL Ltd (SERBIA) | |

| Address: | Arsenija Čarnojevića br.52a/4 |

| Postal Code: | 11070 |

| City: | Belgrade |

| Area: | Belgrade |

| Country: | SERBIA |

| Telephone: | (+381)-11-2129794 |

| Fax: | (+381)-11-3116778 |

| e-mail: | |